Bar Bending Machine Pdf

By Diego Verdi Cabel. SIWES REPORT BY TUNDE OYEDOTUN VICTO R 12BCOO1914 GEC 429 Page 42 From BS code 81101997 clause 3815.

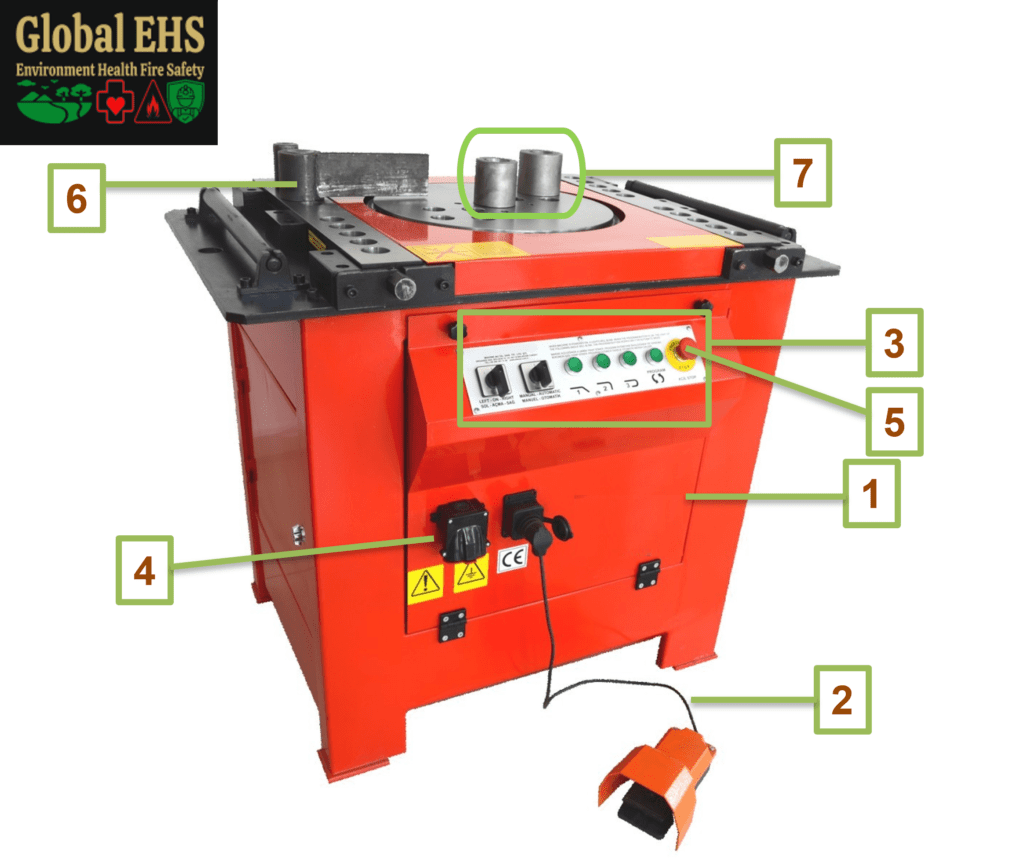

Bar Bending Machine How Does It Work And How To Operate

For short holes the bar may support on the headstock spindle end only.

. Commonly used equipment include box and pan brakes brake presses and other specialized machine pressesTypical products that are made like this are boxes such as electrical enclosures and rectangular ductwork. Register now for free. Download Free PDF View PDF.

We offer forming capabilities of up to 230 ton 10 long parts robotic press brake cells a semi-automatic panel bender and multiple CNC press brakes. Here is the steel weight calculation formula including steel plate tube bar round square flat hexagonal steel rebar angle steel brass copper etc. Download Free PDF Download PDF Download Free PDF View PDF.

The tapered bar of the lathe machine can be set with different angles to the spindle axis. Problems 1-1 through 1-4 are for student research. Figure A1514 Grooved round bar in bending.

Unbraced column- where the lateral loads are resisted by the bending action of the column. Arab Emirates is the one best Industrial Safety Equipment Dealers we offer Power Tool Accessories Cutting And Milling Tools Cutting Grinding Tools Abrasive Tools In Dubai UAE. The best part of this post is you can view and download the all Civil engineering IS-code books in PDF.

Procedure Cut mild steel rod of 25mm Ø in 125mm length from long bar by using power hack saw or ordinary hack saw. A link connects the sliding block to the cross slide. It is placed at some intermediate point to prevent the work piece from bending due to its own weight and vibrations setup due to the cutting force.

21Pack Solid Carbide Inserts Holder Boring Bar Wrench Lathe Turning Tools E7H2. σ0 Mc l where c d2 and I πd464. Search the worlds information including webpages images videos and more.

Highway Bridge Superstructure Approaches to Design and Analysis. Use the search bar on the table to find the specific IS codebook as per your requirement. Reprinted with permission from Machine Design a Penton Media Inc.

Google has many special features to help you find exactly what youre looking for. Youll know this when you move to free weights later because the same weight will be harder to bench. Machine shop notespdf 1.

Bar stock also colloquially known as blank slug or billet is a common form of raw purified metal used by industry to manufacture metal parts and products. It is taken from RL. Our mission statement.

Less muscles work overall as a result. σ0 FA where A πd24. You cant bench the bar in a diagonal line to keep your shoulders safe.

Main Parts and Its Working Principle. We utilize a state-of-the-art ERP bar coding system to track your parts from initial material purchase to part completion and final delivery. The most common shapes are round circular cross-section rectangular square and hexagonal.

The second example models a 1 kg mass moving horizontally along a steel E 207 GPa bar 100 mm long with a 10 mm diameter and striking the end of the bar with a velocity of 1 msec. A bar is characterised by an enclosed invariant. Reading and writing around sheet metal fabrication machining mechanical engineering and machine tools for metals.

7 x 14Mini Metal Lathe Machine 550W Variable Speed 2250 RPM 34HP Upgraded 20. Bending is a manufacturing process that produces a V-shape U-shape or channel shape along a straight axis in ductile materials most commonly sheet metal. Download Free PDF View PDF.

Techpilot is the leading online marketplace for custom made parts in europe and connects more than 16000 buyers with 24000 suppliers. 1030 Mechanical Engineering Design Figure A1513 Grooved round bar in tension. 436 thoughts on Theoretical Steel Weight Calculation Formula 30.

You dont have to balance the bar the machine does. Unimat Manuals catalogs Digital Scans PDF Format Accesories Technical. The boring bar supports the cutter for holding operations on jobs having large bore diameters.

Arrange the tools as specified above from the. Download Free PDF Download PDF Download Free PDF View PDF. In order to search the specific IS book enter the code number Ex.

τ0 Tc. Worse you dont decide how the bar or weight moves. For long work the bar is supported on the spindle end and on the column bearing block.

Shigleys Mechanical Engineering Design. Problems 1-1 through 1-4 are for student research. Figure A1515 Grooved round bar in torsion.

456 dont include the IS before the code number in search. Norton Machine Design Prentice Hall 1996 It is assumed that the correction for the mass of the struck bar reduces the efficiency to η. Bar stock is available in a variety of extrusion shapes and lengths.

To avoid the bending of the workpiece due to the cutting forces acting by the tool exactly opposite to the tool support is provided and it is moving along with the tool called as follower rest.

Bar Bending Machine How Does It Work And How To Operate

Safetyforall01 Bar Bending Machine Checklist Facebook

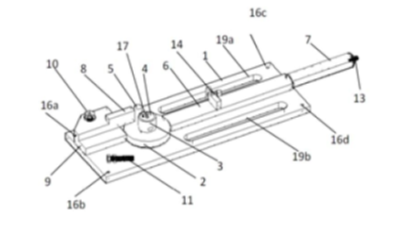

An Experimental Study Of Improvised Portable Manual Rebar Bender

02 Bar Bending Machine Pdf Drl Project Check List For Bar Bending Machine Project Name Equipment No Contractor Name Inspection Date Equipment Course Hero

Comments

Post a Comment